In 2019 we learned together during Chapter 2 of the COMALA (Pottery Learning Community). One of the main topics of that chapter was the detailed study of furnaces and burning. We witnessed, for example, the impressive traditional burning of comales by the teacher Francisca Ocampo, in Atzompa and we built models of each of the kilns of the participating pottery towns, which were later exhibited in the retrospective exhibition Explorations and Roots.

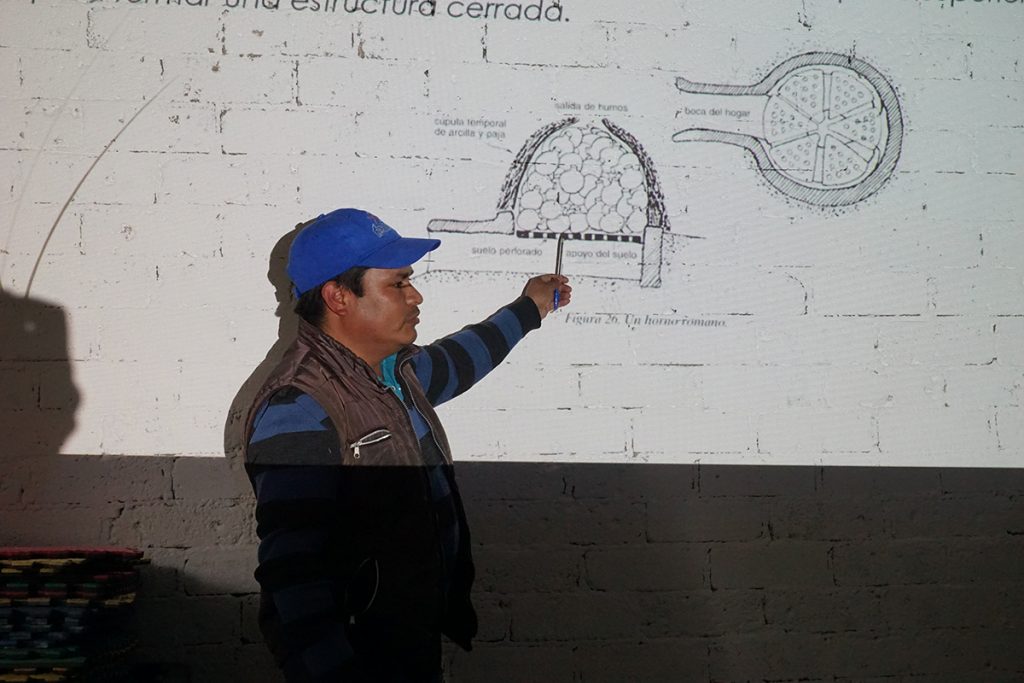

During several sessions we had the pleasure of receiving Domingo Martínez, a master potter and expert in kilns from the Pottery Studies Center in San Miguel Tenextatiloyan, Puebla. Domingo shared his knowledge about the types and history of kilns, good practices during burning, and what we must take into account to build and improve a kiln.

“We are doing physics… we are architects, designers, mathematicians… that is our job”

—Domingo Martínez, potter and expert in traditional kilns.

We close with a flourish by doing the best we know how to do: working in community. Together we built the first Improved Traditional Oven from Oaxaca, in the house of the teacher Francisca, a potter from Santa María Atzompa. It was magical to see the earth slowly turn into the thick but precise walls of the oven, under Domingo's direction.

As a curious fact, when construction began, Francisca found a apaxtle buried in the space designated for the oven a great omen! After two days of measuring, calculating, mixing mud and cutting bricks, we celebrate the end of the construction with a small ritual.

Jaguar It is the name with which Francisca and her husband Memo affectionately decided to call the oven that we built in their house-workshop. This construction practice is a open, accessible and appropriate technology, easy to share and it has enormous benefits for potters who fire in open-draft cylindrical kilns. Only basic knowledge of masonry and a fairly small economic investment are needed.

As part of the process, the design of a Construction Manual for Improved Traditional Ovens with the notes that the potters made. Later we will replicate and share this knowledge in other communities.

A few weeks after finishing construction, we witnessed the first kiln burn, which significantly improved the trade of this pottery family. We wholeheartedly thank the potters who joined the construction, as well as the volunteers and the Innovating team, always at the foot of the canyon in this type of collective activities.

The mud lives.

Photos by Fanel Reyes

The Mud Lives!